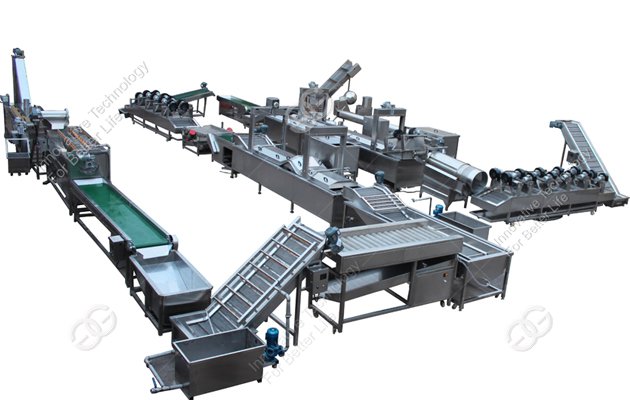

Description:

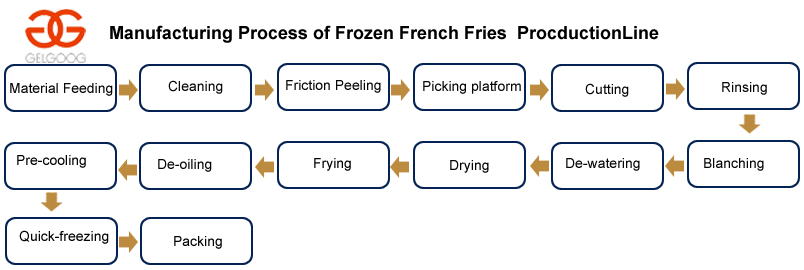

Process flow of frozen French fries includes potato cleaning peeling,cutting, rinsing, blanching,dewatering, frying, deoiling, mixing materials, freezing, weighing and packing.

| Item | Parameter |

| 1Elevator |

0.75kw/380v/50Hz 2000*800*2000mm |

| Cleaning and Peeling Machine |

4.75kw/380v/50Hz 1800*900*1500mm |

| Sorting Conveyor |

0.75kw/380v/50Hz 3000*900*900mm |

| Potato Cutting Machine |

1.5kw/380v/50Hz 950*800*950mm |

| Rinshing Machine |

5kw/380v/50Hz 3500*1600*900mm |

| Blanching Machine |

70kw/380v/50Hz 3500*1600*950mm |

| Vibrating Dewatering Machine |

1.5kw/380v/50Hz 1500*1000*1300mm |

| Sorting Conveyor |

0.75kw/ 380V/50Hz 4000*800*1000mm |

| Air Cooling Machine |

15kw/380v/50Hz 4000*1200*1400mm |

| Elevator |

0.75kw/380v/50hz 2500*800*1300mm |

| Electric Continuous Fryer Machine |

120kw/380v/50Hz 4000*1200*2600mm |

| Vibrating Deoiling Machine |

1.5kw/380v/50Hz 1500*1000*1300mm |

| Air Drying Machine |

8kw/380v/50Hz 4000*1200*1600mm |

| Elevator |

0.75kw/380v/50Hz 2400*800*2200mm |

| Flavoring Machine |

50kw/380v/50hz 2500*900*1500mm |

Mobile: 0086-185-3993-1566

Tel: 0086-371-63398802

E-mail: wendy@machinehall.com

Skype: wendymachinehall

Address:No. 100, Shangdu Road, Zhengzhou City, Henan Province, China.

Today, GELGOOG is creating value for its customers all over the world by constantly elevating its products and services. GELGOOG is dedicated to developing business with you and becoming your strong and trusted business partner. more info

Leave Message